DECORATING METHODS

BRANDING TECHNOLOGY OF PROMOTIONAL MUGS

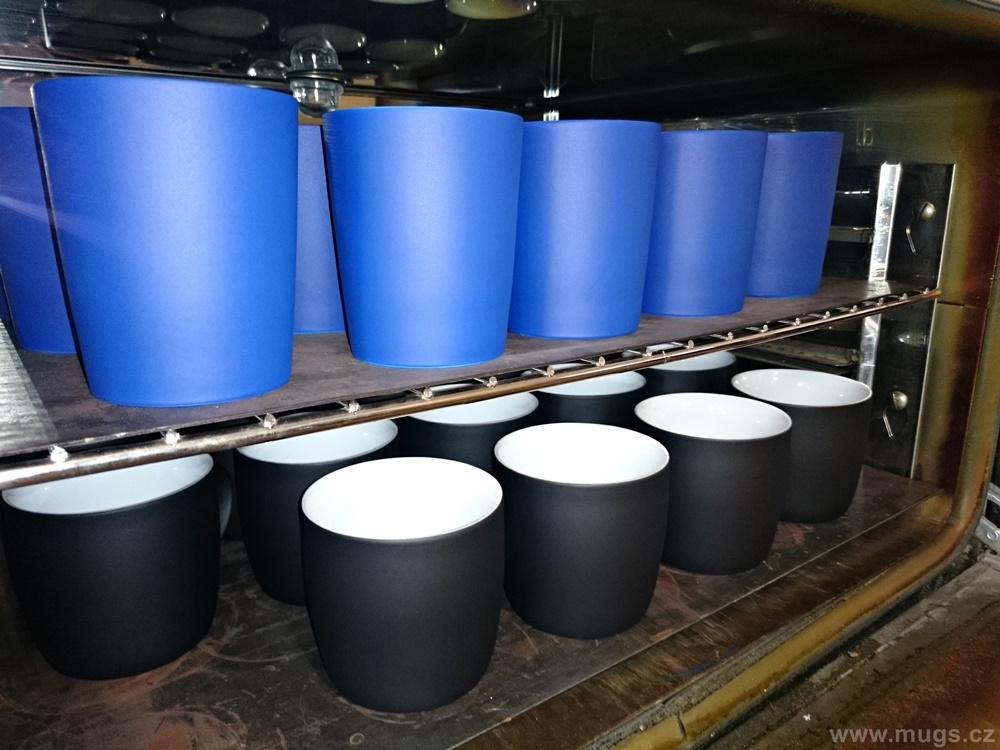

Glazing and firing

Advertising and Corporate porcelain, ceramics, glass are colored by special water-based glaze. It is based on the unique composition of the heat-curing resins for brilliant decoration of glass and ceramics. This water-soluble paint is designed directly to decorate consumer products. Colors are available in a huge range of options, you can choose any color from the Pantone sampler.

Glaze that we use is a high performance organic color, which is very chemically and mechanically resistant. Color constancy (chemical and mechanical) allows to use it as gift items, glass, decorative lights, chandeliers, cups, eating and drinking sets, etc. When applied to object the water evaporates from color and polymerization occurs. A small amount of slowly evaporating solvent helps to decanting into a continuous film. The heat, after a film is obtained helps to reach chemical bonds. For a complete hardening of glaze and for greater resistance of standard color it is needed to reach a temperature of about 200 °C.

On the basis of certifications issued by the Regional Health Officer we are authorized to issue a safety health certificate (certificate of conformity).

.jpg)

.jpg)

Special colour coats

We produce various custom surfaces. Our speciality is glossy and mat glaze and also metalic colour coat or gold and silver glaze.

.JPG)

.JPG)

Colored glaze fired at high temperatures - 9 shades of colors

We glaze selected Czech porcelain mugs for high-temperature firing from 100 pcs, with a lifetime warranty against paint abrasion. It is a range of 9 color shades in a glossy design, according to illustrative photos: black, red P 187C, yellow P 142C, blue P 181C, light green P 577C, brown P 4625C, green P 342C, light blue P 550C, orange P 165C.

Pantone color glazed handles and tiny lines

Sandblasting

Sandblasting is one of the best and most stable ways to create a logo on the porcelain and glass object. You don't have to worry about any damage caused by a dishwasher or just simply use it, because the logo is in the depth of the porcelain/glass and can't be washed away. The technology consists of fine sandblasting through a template that is bonded to porcelain/glass. The logo at the blasting spot becomes dull. The clear and frosted porcelain and glass can also produce very small (few) letters and fine details.

.JPG)

Sandblasting with handmade colouring

We are a specialist for sandblasting into porcelain/glass with handmade colouring. Colors are available in a huge range of options, you can choose any color from Pantone sampler. For a complete hardening of glaze and for greater resistance of standard color it is needed to reach a temperature of about 600 °C.

.JPG)

Sandblast Imitation

3D printing technology "Milk" colour with high firing at 900 °C. Sandblast imitation is suitable for glass logo brand, very durable and ideal for daily use in restaurants and caffes.

.JPG)

Printed Decals and CMYK colour printing

We decorate glass, porcelain, ceramic, stainless steel and more. The image is broken down into four essential colours: Cyan, Magenta, Yellow and Black (known as CMYK). Most creative software can store an image in CMYK format, but be careful as the monitor may not give a Pantone accurate version of the image, it is best to send graphic files with a printed visual. After decoration, follows firing at 800°C, 600°C, 200°C in the intermediate chamber and firing electric furnaces. We can combine decorative techniques, decals, waterglaze spraying, sandblasting and painting/sandblasting, so we can achieve extraordinary results.

.JPG)

.JPG)

Sublimation Printing

Sublimation technology has been used in printing for some time, but has only recently become available for ceramic and porcelain decoration. Special inks are printed onto the surface of a coated paper, but not as a permanent print. The paper releases the print when heat is applied, when in contact with the prepared surface of a beaker.

SP uses organic dyes allowing a stunning combination of colours. It is a more versatile finish than fired enamel colours, as it does not have to withstand a kiln firing. However, some loss of vividness can arise if exposed to too much bright light and heat and the protective film can lose its lustre if washed frequently in harsh dishwasher cycles.

Nevertheless, it is bold and with the right artwork opens up brilliant reproduction possibilities straight from computer screen.

Magic mugs

Magic mugs are several years a permanent fixture of gift and promotional items. We are a leading manufacturer of injection technology magic mugs in the Czech Republic. At first glance the classic mug, however, once you fill the cup with hot liquid, it appears your brand. After cooling, the logo disappears. The effect can be repeated indefinitely. VIDEO

Cardboard

Boxes and small boxes made to order in size, disassembled, approx 1000 x 700 mm (B1). There we have about 100 cutting tools, mainly for gift wrapping mugs and glasses. These boxes and small boxes are made mostly of microwaves. Cardboard is also possible in our silkscreen print, before or after the segmented. Boxes are available in basic white or color is to choose from 11 colors.

.JPG)

.JPG)

.JPG)

.JPG)